Description

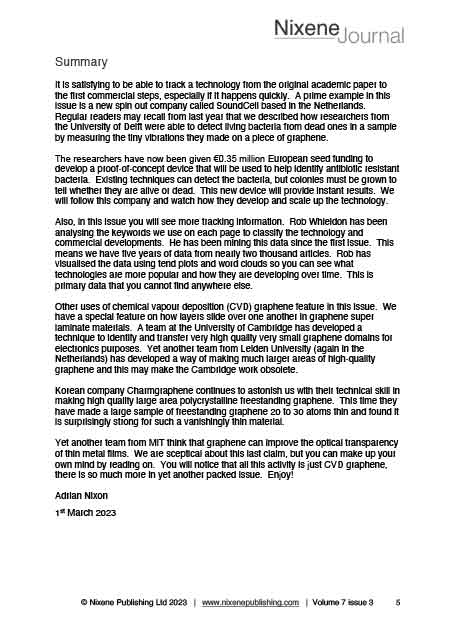

It is satisfying to be able to track a technology from the original academic paper to the first commercial steps, especially if it happens quickly. A prime example in this issue is a new spin out company called SoundCell based in the Netherlands. Regular readers may recall from last year that we described how researchers from the University of Delft were able to detect living bacteria from dead ones in a sample by measuring the tiny vibrations they made on a piece of graphene.

The researchers have now been given €0.35 million European seed funding to develop a proof-of-concept device that will be used to help identify antibiotic resistant bacteria. Existing techniques can detect the bacteria, but colonies must be grown to tell whether they are alive or dead. This new device will provide instant results. We will follow this company and watch how they develop and scale up the technology.

Also, in this issue you will see more tracking information. Rob Whieldon has been analysing the keywords we use on each page to classify the technology and commercial developments. He has been mining this data since the first issue. This means we have five years of data from nearly two thousand articles. Rob has visualised the data using tend plots and word clouds so you can see what technologies are more popular and how they are developing over time. This is primary data that you cannot find anywhere else.

Other uses of chemical vapour deposition (CVD) graphene feature in this issue. We have a special feature on how layers slide over one another in graphene super laminate materials. A team at the University of Cambridge has developed a technique to identify and transfer very high quality very small graphene domains for electronics purposes. Yet another team from Leiden University (again in the Netherlands) has developed a way of making much larger areas of high-quality graphene and this may make the Cambridge work obsolete.

Korean company Charmgraphene continues to astonish us with their technical skill in making high quality large area polycrystalline freestanding graphene. This time they have made a large sample of freestanding graphene 20 to 30 atoms thin and found it is surprisingly strong for such a vanishingly thin material.

Yet another team from MIT think that graphene can improve the optical transparency of thin metal films. We are sceptical about this last claim, but you can make up your own mind by reading on. You will notice that all this activity is just CVD graphene, there is so much more in yet another packed issue. Enjoy!

Adrian Nixon

1st March 2023