Description

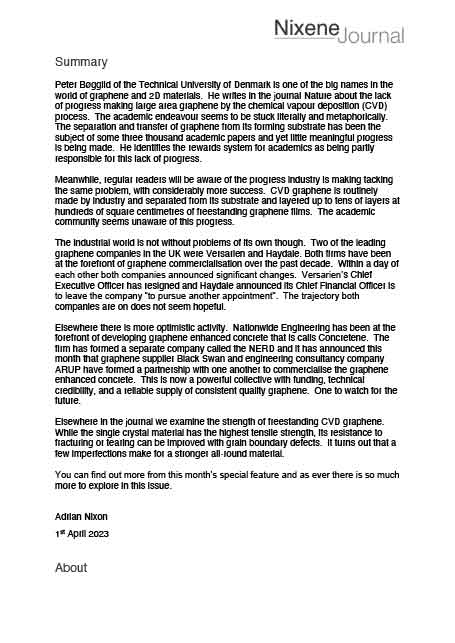

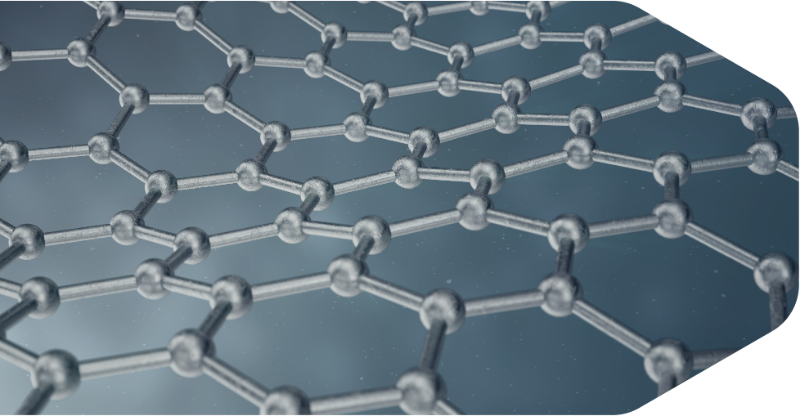

Peter Bøggild of the Technical University of Denmark is one of the big names in the world of graphene and 2D materials. He writes in the journal Nature about the lack of progress making large area graphene by the chemical vapour deposition (CVD) process. The academic endeavour seems to be stuck literally and metaphorically. The separation and transfer of graphene from its forming substrate has been the subject of some three thousand academic papers and yet little meaningful progress is being made. He identifies the rewards system for academics as being partly responsible for this lack of progress.

Meanwhile, regular readers will be aware of the progress industry is making tacking the same problem, with considerably more success. CVD graphene is routinely made by industry and separated from its substrate and layered up to tens of layers at hundreds of square centimetres of freestanding graphene films. The academic community seems unaware of this progress.

The industrial world is not without problems of its own though. Two of the leading graphene companies in the UK were Versarien and Haydale. Both firms have been at the forefront of graphene commercialisation over the past decade. Within a day of each other both companies announced significant changes. Versarien’s Chief Executive Officer has resigned and Haydale announced its Chief Financial Officer is to leave the company “to pursue another appointment”. The trajectory both companies are on does not seem hopeful.

Elsewhere there is more optimistic activity. Nationwide Engineering has been at the forefront of developing graphene enhanced concrete that is calls Concretene. The firm has formed a separate company called the NERD and it has announced this month that graphene supplier Black Swan and engineering consultancy company ARUP have formed a partnership with one another to commercialise the graphene enhanced concrete. This is now a powerful collective with funding, technical credibility, and a reliable supply of consistent quality graphene. One to watch for the future.

Elsewhere in the journal we examine the strength of freestanding CVD graphene. While the single crystal material has the highest tensile strength, its resistance to fracturing or tearing can be improved with grain boundary defects. It turns out that a few imperfections make for a stronger all-round material.

You can find out more from this month’s special feature and as ever there is so much more to explore in this issue.

Adrian Nixon

1st April 2023