Description

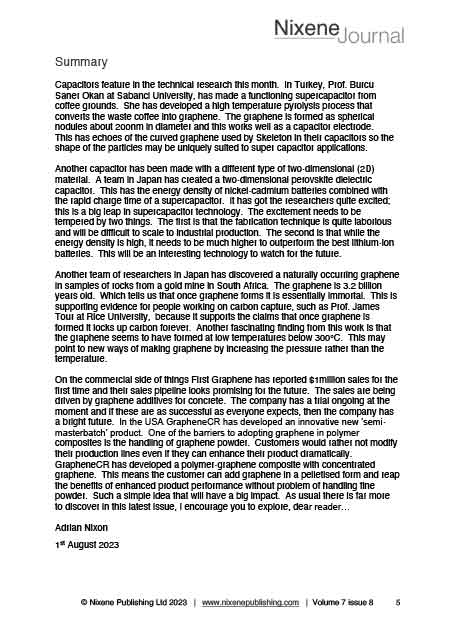

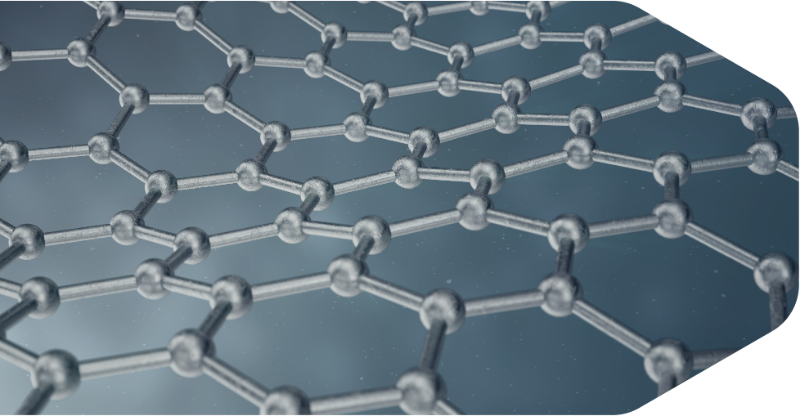

Capacitors feature in the technical research this month. In Turkey, Prof. Burcu Saner Okan at Sabanci University, has made a functioning supercapacitor from coffee grounds. She has developed a high temperature pyrolysis process that converts the waste coffee into graphene. The graphene is formed as spherical nodules about 200nm in diameter and this works well as a capacitor electrode.

This has echoes of the curved graphene used by Skeleton in their capacitors so the shape of the particles may be uniquely suited to super capacitor applications.

Another capacitor has been made with a different type of two-dimensional (2D) material. A team in Japan has created a two-dimensional perovskite dielectric capacitor. This has the energy density of nickel-cadmium batteries combined with the rapid charge time of a supercapacitor. It has got the researchers quite excited; this is a big leap in supercapacitor technology. The excitement needs to be tempered by two things. The first is that the fabrication technique is quite laborious and will be difficult to scale to industrial production. The second is that while the energy density is high, it needs to be much higher to outperform the best lithium-ion batteries. This will be an interesting technology to watch for the future.

Another team of researchers in Japan has discovered a naturally occurring graphene in samples of rocks from a gold mine in South Africa. The graphene is 3.2 billion years old. Which tells us that once graphene forms it is essentially immortal. This is supporting evidence for people working on carbon capture, such as Prof. James Tour at Rice University, because it supports the claims that once graphene is formed it locks up carbon forever. Another fascinating finding from this work is that the graphene seems to have formed at low temperatures below 300°C. This may point to new ways of making graphene by increasing the pressure rather than the temperature.

On the commercial side of things First Graphene has reported $1million sales for the first time and their sales pipeline looks promising for the future. The sales are being driven by graphene additives for concrete. The company has a trial ongoing at the moment and if these are as successful as everyone expects, then the company has a bright future. In the USA GrapheneCR has developed an innovative new ‘semi-masterbatch’ product. One of the barriers to adopting graphene in polymer composites is the handling of graphene powder. Customers would rather not modify their production lines even if they can enhance their product dramatically. GrapheneCR has developed a polymer-graphene composite with concentrated graphene. This means the customer can add graphene in a pelletised form and reap the benefits of enhanced product performance without problem of handling fine powder. Such a simple idea that will have a big impact. As usual there is far more to discover in this latest issue, I encourage you to explore, dear reader…

Adrian Nixon

1st August 2023